To resist the lateral load caused by an earthquake, shear walls are installed in soft-story buildings. Shear walls are strongly suggested for retrofitting by seismic experts. A shear wall resists the lateral forces and is placed parallel to the wall’s plane.

The rigidity and distribution of columns in weak-story buildings is a tedious task. The placing of shear walls is protection while we implement seismic solutions.

If you are an owner of a weak building and looking for answers, building shear walls can solidify the structure. However, it is more costly than other simple soft-story retrofit solutions. Let’s take an insight into the types and implementation processes of shear wall construction.

Contents

- What Is a Shear Wall and Why Do Buildings Need Them?

- Advantages of Shear Walls

- Which Types of Structures Need Shear Walls?

- Different Types and Shapes of Shear Walls

- Wooden framing with vertical studs and sheathing

- Steel Sheets

- Diagonal Braces

- Moment Frames

- Reinforced Concrete Shear Wall

- Concrete Block Shear Wall

- Steel Shear Wall

- Tips for installing Shear Walls

- How do you choose a contractor to build concrete shear walls in Los Angeles?

What Is a Shear Wall and Why Do Buildings Need Them?

Shear walls are constructed to reinforce concrete framed structures to resist lateral forces that are likely to occur in a situation like an earthquake. These walls are generally used in high-rise buildings to avoid the effect of seismic forces.

In building design, shear walls can be built in concrete or steel (typically concrete) and typically surround the core of the building, which is where the elevator and stairs are. The shear walls help resist the effects of wind and earthquake by providing a lateral resistance that is not provided by a frame where members are pinned together. In this activity, a shear well can be implemented with a cardboard square attached to the frame.

In reinforced concrete framed structures, the impact of wind forces increases as the height of the building increases. Codes of practice impose limits on horizontal movement or sway.

-

- Shear walls protect the buildings in the following ways.

- Overhang and cantilever projection existence in weak-story.

- Infill wall material properties.

- Soil class and properties.

Advantages of Shear Walls

In concrete structures, shear walls include walls on all sides of the building, extending its entire height. The contractors prefer to build long walls with fewer openings to prevent sudden displacement.

A suitable design procedure includes the construction of the shear walls by installing steel reinforcing bars that extend across the joint between the walls and the foundation.

Which Types of Structures Need Shear Walls?

Using classifications derived from the International Building Code, monolithic shear walls are classified as short, squat, or cantilever according to their height to depth ratio. Generally, shear walls are either plane or flanged in sections, while core walls consist of channel sections.

Almost all houses have external shear walls, but internal shear walls are typically found only in larger homes and high-rise buildings. The height of the building is the deciding factor in installing the shear walls. They provide a lateral force-resisting system.

Different Types and Shapes of Shear Walls

The size, shape, and type of shear wall are constructed as per the infrastructure of the building. Some of the types used in common include.

-

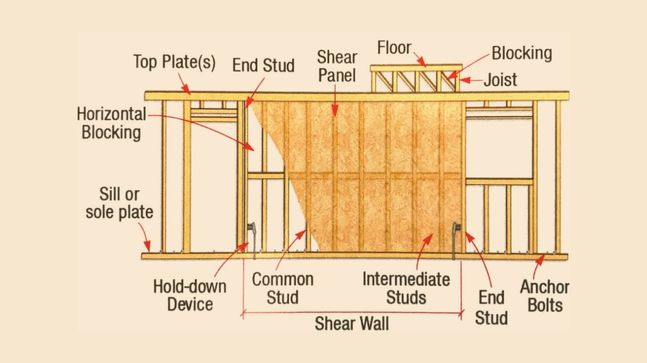

Wooden framing with vertical studs and sheathing

The wood frame with vertical studs is good enough to protect the building. The wood is covered with plywood or oriented strand board (OSB) in modern structures. This technique can resist moderate lateral pressure.

-

Steel Sheets

For buildings having pressure on the upper side, the wood frames are replaced with steel sheets.

-

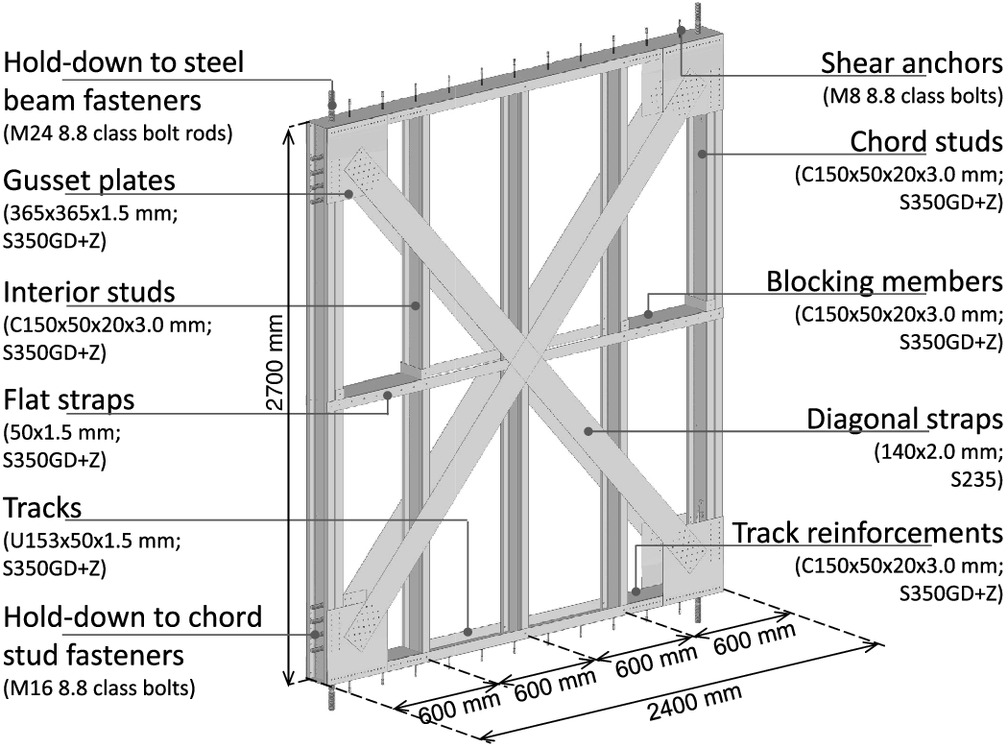

Diagonal Braces

A diagonal frame made of steel or other material provides more resistivity than regular steel or wooden frames.

-

Moment Frames

These frames are shear walls with an option to install windows or doors. However, this is an expensive option. Depending on the materials used to construct shear walls, they are designed in various types, which are:

-

Reinforced Concrete Shear Wall

The method is used for residential buildings supporting horizontal and vertical directions. However, bars are tightly spaced and anchored at the end of each wall. Boundary elements or barbells are the terms used to describe the end zones of RC shear walls. The thickness of an RC shear wall is determined by considering the building’s thermal insulation requirements, age, and the number of floors.

-

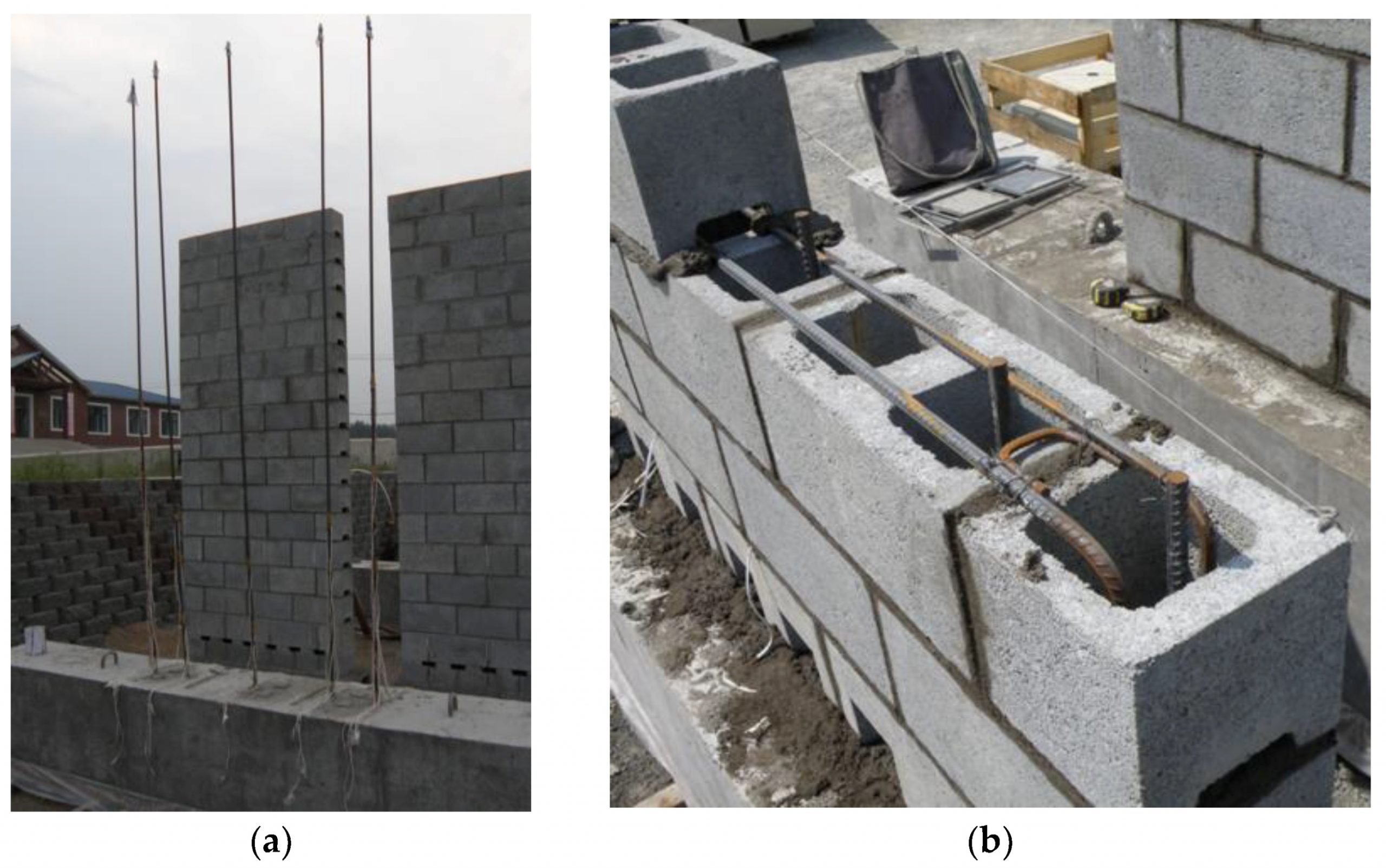

Concrete Block Shear Wall

The hollow concrete blocks and steel reinforcing bars are used to increase the effect of concrete block masonry against seismic loads. The method includes both vertical and horizontal orientations. The blocks are distributed through concrete block spaces. Fresh concrete grout is poured into the space after inserting bars in concrete block masonry and allowed to harden.

-

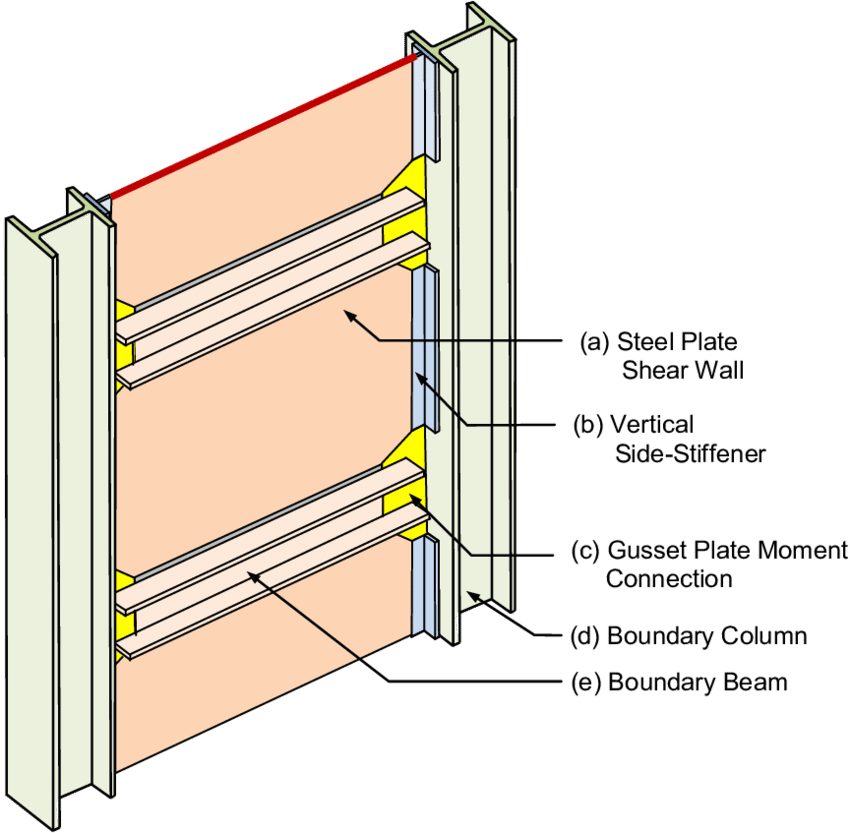

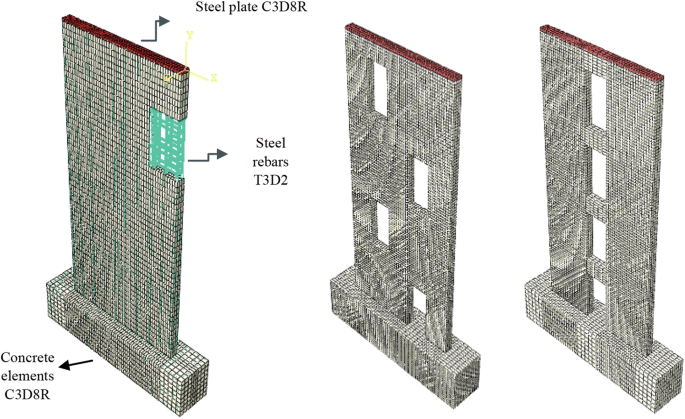

Steel Shear Wall

Consists of a steel plate wall, boundary column, and horizontal floor beam. The action of the steel shear wall is more like a plate girder. Steel plate wall acts as a web of a plate girder, boundary columns act as flanges, and horizontal beams act as stiffeners of a plate girder.

Tips for installing Shear Walls

Installing sheer walls requires technical and architectural skills. You need to contact a soft story retrofit contractor with experience in a similar field. Here are some tips that will help you build concrete shear walls.

-

- Checking the building material code is the first step to deciding the suitable OSB or plywood. It will ensure smooth sheathing and the DOC product standard. Using PS1 for plywood and PS2 for OSB will be beneficial.

- Select panels above 12 feet in height for a sheathing project. The longer the panel, the less blocking is required.

- Installing a vertical panel is more effective than horizontal placement, as each panel contains an axis to strengthen the structure.

- Fasten the sheathing to the frame using nails. The architect creates their size and spacing, and he already keeps a provision to place them well.

- Finally, all sheathing must be mechanically attached to the foundation walls with metal connectors.

How do you choose a contractor to build concrete shear walls in Los Angeles?

Seismic retrofit contractors sometimes juggle to select the most suitable form of shear walls. Sometimes, the building codes do not mention shear wall construction.

As per the damage report prepared for the city of Los Angeles, the losses were minimal in the building having shear walls with plywood or steel frames.

Before you choose a contractor to build shear walls, it is wise to check the building for other types of weaknesses like the need for foundation repair, and so on.

-

- Choosing the best soft story retrofit contractor for the construction of a shear wall structure is recommended by the architects.

- Before you proceed further, you must evaluate the contractor’s portfolio based on the projects handled by him. Also, make sure to choose one who has:

- Systematic repair plan after analyzing your project.

- How convenient is the contractor for providing soft story retrofit solutions?

- What is their approach to fixing the structural damages in the last earthquakes?

- How efficiently can they build shear walls?

Depending on the answers to these questions, you can choose a construction contractor in Los Angeles, California. We have the experience to understand metallurgy, the qualities of existing concrete, the performance of buildings on shake tables, and existing building materials such as the construction of shear walls. The building code, and so on.

Depending on measuring these parameters, we provide an estimate in the cost-saving mode. Request for a high–quality, time-framed, most appropriate construction as per seismic guidelines of Los Angeles.